The global vinyl flooring market size was estimated at around USD 26 billion in 2018 and is expected to expand at a CAGR of 7.4% from 2019 to 2026. Increasing demand for low-maintenance, cost-effective, and lightweight construction materials in residential construction is likely to drive the vinyl flooring market during the forecast period.

This is because of the many benefits of vinyl flooring such as easy installation and maintenance, cost-effectiveness, and moisture resistance, stimulating the demand in the region. In addition to this, increasing technological advancements in the manufacturing process have led to the growth of vinyl flooring in terms of performance, installation, and design. Moreover, the demand for vinyl flooring products in the region has increased due to rising per capita income and standard of living. In addition, increasing renovation activities are also contributing to the growth of the vinyl flooring market.

The following section references the standard T/CSUS 02-2020, published by China Urban Science Research Council

Stone-Wood-Polymer Composite Flooring : A composite flooring made of rigid non-foaming composite material made of calcium carbonate powder, wood fiber material, PVC resin powder and other additives as the base material and processed with a decorative surface.

Moisture-Proof Film : Moisture-proof material that is placed on top of the substrate to prevent the moisture content of the resilient flooring from being affected by the evaporation and penetration of moisture in the substrate.

Glue Down Installation:The flooring is installed on the substrate with adhesive.

Float Click Installation:The floor is directly installed on the grass-roots level through the locking connection.

- Main materials

1.1 The selection of raw materials of stone wood plastic flooring should conform to the provisions of the relevant national product standards in force, and it is appropriate to use energy-saving, waste-friendly, environmentally friendly raw materials, and shall not use the materials eliminated by national order.

1.2 The specification size of stone wood plastic flooring has the following.

| Type | Indicator | |||

| Length | 1210mm | 1500mm | 600mm | |

| Standard board | Width | 192mm | 176mm | 600mm |

| Thickness | 7mm | 5mm | 4mm | |

| Non-standard board | Specifications | OEM/OEM |

- Auxiliary materials

2.1 The selection of auxiliary materials for stone wood plastic flooring paving should comply with the current national standard “limit of harmful substances in indoor decoration materials adhesive”, “indoor environmental pollution control standards for civil construction projects” and “PVC block plastic flooring adhesive” of the relevant provisions.

2.2 The adhesive used for stone wood plastic flooring paving should be used according to the design requirements, and the single-component dispersion water-based adhesive can be selected.

2.3 lock – suspension paving method using moisture-proof film can choose polyethylene, foamed polyethylene, ethylene – vinyl acetate copolymer and other moisture-proof materials. - Design

3.1 The selection of stone wood plastic flooring should be coordinated with the interior decoration design, and the plane style, surface decoration style selection, material selection and performance and construction design under the premise of conforming to the aesthetics and use function.

3.2 The design of stone wood plastic flooring should be integrated with architectural design and interior decoration design.

3.3 The design of stone wood plastic flooring should be modulo coordinated with the building set, and the space of flooring paving is suitable to adopt interface positioning method, and the positioning of flooring can be controlled by setting modulo grid.

3.4 On the basis of modulus coordination, should follow the principle of burning specification and multiple combination, the specification of this floor is selected or standardized design.

3.5 The design of stone wood plastic flooring should meet the performance requirements of wear resistance, anti-pollution, easy cleaning, corrosion resistance, fire prevention, anti-static, etc. The flooring material and structure for kitchen, bathroom, basement, bedroom and other rooms should also meet the performance requirements of waterproof and anti-slip.

3.6 The design of stone wood plastic flooring should be selected according to the actual use of scenes and parts of its wear resistance, stain resistance, corrosion resistance and other aspects.

3.7 The design of stone wood plastic flooring is suitable to adopt building information model technology and architectural design, construction for system integration, to achieve the integration of the whole process of design, production and construction.

4. Structure design

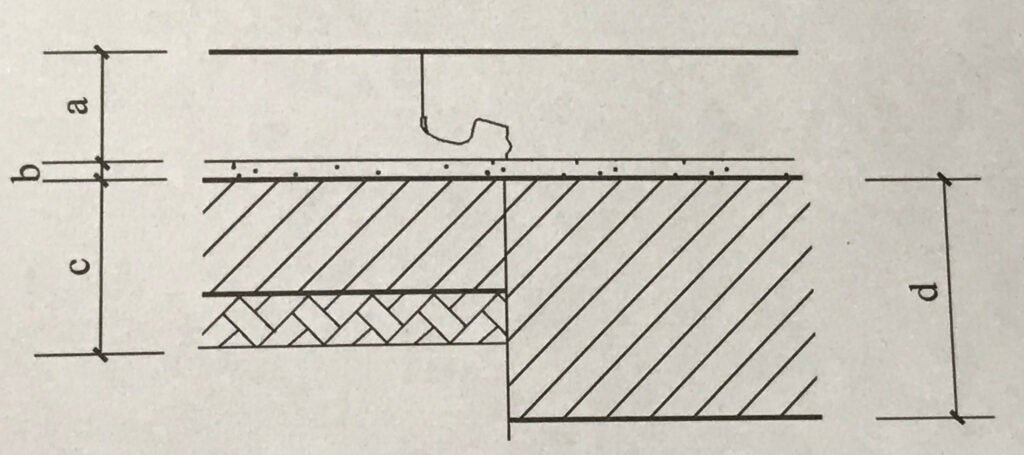

The stone wood plastic flooring laying method can be divided into glue installed straight paving method and locking – suspension paving method.

4.1 When using glue installed straight paving method, the stone wood plastic flooring should be paved on the grass-roots level brushed with adhesive, and the glue installed straight paving method should not use moisture-proof film.

a – stone wood plastic flooring; b – adhesive layer; c – floor base; d – floor base

4.2 When using the lock – suspension paving method, should be laid on the grass-roots level above the moisture-proof membrane, stone wood plastic flooring directly through the lock connection installed in the moisture-proof membrane.

a – stone wood plastic flooring; b – damp-proof membrane; c – floor grass-roots level; d – floor grass-roots level

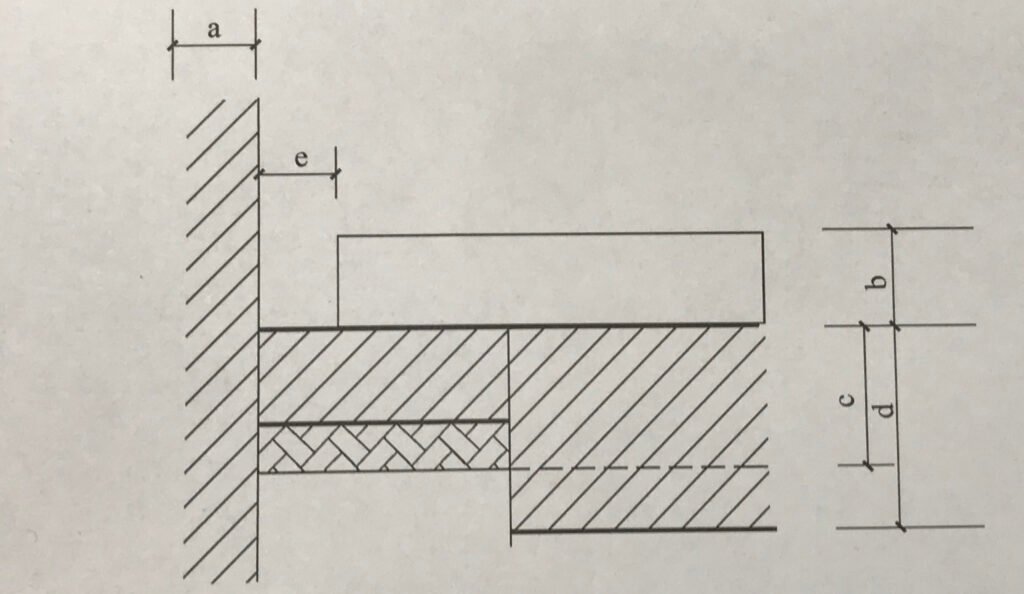

4.3 The design of the expansion joint shall conform to the following provisions.

4.3.1 Expansion joints should be set up around the wall and other fixed objects

a – the wall; b – stone wood plastic flooring; c – the floor base; d – the floor base; e – expansion joints

4.3.2 The maximum installation length or width of the stone wood plastic floor should have expansion joints when it exceeds 20M

4.3.3 The expansion joint width should be set according to the size of the installation area, and is suitable for 6mm~15mm

4.3.4 The selection of skirting should be matched with the material of stone wood plastic flooring.

5 Construction

5.1 General provisions

5.1.1 Stone wood plastic flooring paving should be in strict accordance with the construction process, and each process should be accepted in the previous process before construction.

5.1.2 The stone wood plastic flooring should be placed smoothly and fixed firmly in the transportation process.

5.1.3 Stone wood plastic flooring specific paving should meet the relevant provisions of the following table.

| Pavement temperature (℃) | Sun exposure | Substrate conditions | Partition conditions |

| 10~30 | Avoid long time large area irradiation | Smooth, dry, clean, no grease, no floating soil, no obvious protrusions and construction waste | Installation of the maximum length or width of more than 20m to partition, partition gap reserved 6mm ~ 15mm |

5.1.4 Stone wood plastic flooring paving should be carried out in plastering works, plumbing and electrical piping works, concealed works acceptance.

5.1.5 The surface of the substrate should be flat, dry, clean, free of grease and other impurities. When the grass-roots level is concrete floor, its thickness, strength and hardness shall conform to the relevant “Construction Quality Acceptance Specification for Building Flooring Works”, without bulging, sparse or brittle areas, and without structural defects.

5.1.6 The construction unit shall take effective measures to control the construction site of various dust, exhaust gas, waste, noise, vibration and other pollution and hazards caused to the surrounding environment.

5.1.7 Stone wood plastic flooring paving should start from one side of the wall opposite paving, paving way for according to the product type and the actual scene selection of glue installed straight paving method or locking – suspension paving method.

5.1.8 Stone wood plastic flooring paving should comply with the following provisions.

1> The main materials, semi-finished products and finished products used in stone wood plastic floor paving should be inspected on site. Where the safety, energy saving, environmental protection and the main use of functional materials, products, should be in accordance with the construction specifications of each professional project, acceptance specifications and design documents and other provisions for re-inspection, and should be checked and approved by the supervising engineer;.

2> Each construction process shall be quality controlled in accordance with the construction technology standards, and after each process is completed, the construction unit shall self-inspect the construction of the next process only after it meets the requirements.

5.2 Material storage

5.2.1 The stone wood plastic flooring should be stored with the label facing outward, the pile height should not exceed 1m, when the wall has not passed the maintenance period, the distance should not be less than 50cm, neatly placed flat.

5.2.2 According to the different color numbers and batches shipped to the site, they should be registered in order and stacked separately.

5.3 Construction preparation

5.3.1 The varieties, specifications and models of incoming materials shall conform to the provisions of the design documents and shall have the quality certificate or performance test report.

5.3.2 Before paving, the moisture content of the ground measured by the carbonation reaction method should not be higher than 4%.

5.3.3 The stone wood plastic flooring should be rested on the ground for 48H before paving before use.

5.4 Construction points

5.4.1 The paving steps of gluing direct paving method should be grass-roots cleaning, painting interface agent, scraping glue, paving floor, exhausting and compacting, cleaning, etc.

5.4.2 The use of glued straight paving method, grass-roots cleaning should be in line with the following provisions.

1.> Different cleaning methods should be used according to different parts.

2> corners should be cleaned vertically

3> The ground shall be cleaned by sweeping.

4> The ground with dust should be cleaned with vacuum cleaner.

5.4.3 Pre-treatment should be carried out on the opposite side when painting interface agent, and then the painting process should be carried out.

5.4.4 Scraping should be in accordance with the following provisions.

1> A toothed scraper should be used to apply glue evenly on the ground.

2> Gum road height 3mm.

5.4.5 Glued straight paving method of flooring should comply with the following provisions.

1> should be firm and flat.

2> Stone wood plastic flooring on the adhesive layer.

5.4.6 The use of glued straight paving method, floor exhaust compaction should be in a room or a construction surface after laying roller or pushing board to add pressure compact.

5.4.7 Glued straight paving method should use special rubbing glue paper to the surface glue timely cleanup, pavement completion of the ground for cleaning and cleaning.

5.4.8 Locking – suspension paving method of paving steps should be grass-roots cleaning, laying moisture-proof film, installation of flooring, cleaning, etc.

5.4.9 Shop moisture-proof membrane should comply with the following provisions.

1> Damp-proof membrane thickness should be selected from 0.7mm~2.2mm;

2> After the completion of laying, should block the water vapor of the grass-roots level, keep the paved stone wood plastic floor dry.

5.4.10 When using the locking-suspension paving method, the installation of the floor should be carried out on the moisture-proof membrane.

5.4.11 Locking – suspension paving method should be cleaned and cleaned on the ground after the completion of paving.

5.4.12 When installing skirting, the mat should be taken out before installation. The mat block set between the stone wood plastic flooring and the wall and ground fixings should be selected between 6mm~15mm.

5.4.13 Stone wood plastic flooring should be staggered paving, length direction adjacent two rows of flooring end spacing should be within 1/3~2/3 of the floor length.

5.4.14 Skirting should be in full contact with the surface of the floor, and the bonding of the skirting and the grass-roots level should be dense.

5.4.15 In the sizing installation, after the grass-roots cleanup, glue application should be continuous, uniform and appropriate amount.

5.4.16 After the installation of the floor, should promptly remove the adhesive squeezed to the surface of the floor.

5.4.17 The use of gluing straight paving method to complete the floor paving should be left for 24h before use.

5.4.18 The use of locking – suspension paving method to complete the floor paving can be used directly after.

6 Quality acceptance

Allowable deviation and inspection method of stone wood plastic flooring.

| Item | Flatness of the plane | Joint height difference |

| Stone wood plastic flooring | 3.0 | 0.2mm |

| Inspection method | Check with 2m leaning tape and model stopper | Check with steel ruler and model stopper |